-ABOUT US-

We have fulfilled the requirements of our permanent or new ones

customers in various industries across EUROPE for over 25 years.

ISTROMETAL DM Ltd. (s.r.o.) was founded on 10 November 1994.

It was established as a successor to engineering workshops of chemical factory

ISTROCHEM joint stock company (a.s.)

Since the establishment, our main activities consist of METALWORKING,

LOCKSMITH,

AND BOILER MANUFACTURING. We maintain the tradition of classic custom

manufacturing

until today. We have fulfilled the requirements of our permanent or new ones

customers in various industries across EUROPE for over 25 years.

If you asked all of our existing customers what important

characteristics would describe us the best, you would hear in particular:

FLEXIBILITY, RELIABILITY, AND RESPONSIBILITY, that are realized

by top professionals on a professional level.

At the beginning of 2010, we managed to relocate the entire company

to the newly built manufacturing and administrative premises

located in Bratislava, Vrakuňa. Newly built buildings

consist of four parts: MANUFACTURING WORKSHOP, ADMINISTRATIVE

BUILDING,

LOCKSMITH AND BOILER WORKSHOP, AND METALLURGICAL MATERIAL

WAREHOUSE.

In these premises, 60 workers are ready to fulfill all

requirements of existing as well as future customers. All the staff has

extensive experience, which confirms their long-time practice in the field.

ISTROMETAL DM Ltd. (s.r.o.) has always been interested in any business-like

cooperation, the Slovak or a foreign customer. We are also

ready to adapt or expand our production capacity flexibly

according to new customer requirements.

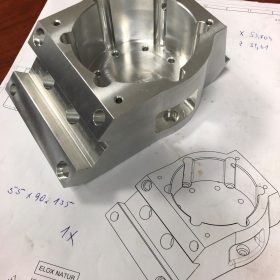

Our constant investment in machine

modernization

and the purchase of the latest CNC machines,

which can meet the increasing demands of customers,

show that we consider expanding productivity to be decisive.

We can deliver your parts that we produce

by our vehicles upon request. Or we will arrange their transport through

verified forwarding companies.

In 2010 we certified our quality management system by ISO 9001

and environmental management system following ISO 14001

successfully, demonstrating our relationship with customers

as well as the environment, which enabled us

to rank among modern European businesses.

During our existence, we have also received several awards, the most important are:

SOCIALLY RESPONSIBLE BUSINESS

STABILITY GOLD SEAL

SIGNIFICANT EXPORTER OF THE SLOVAK REPUBLIC

TRUSTED COMPANY 2018, 2019, 2020

CUTTING AND CNC SHAPED CUTTING

– Band saw cutting

– CNC plasma cutting

– CNC flame cutting

– Oxy-acetylene cutting

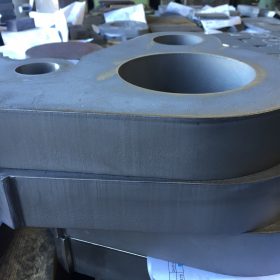

LOCKSMITH AND BOILER MANUFACTURE

– Welding

– Weldments assembling according to drawings

– Bending of metal sheets

– Rolling of metal sheets and logs

-Profile bending rolling

– Compression moulding

METALWORKING AND CNC MANUFACTURE

– Turning and CNC turning

– Milling and CNC milling

– Drilling and CNC drilling

– Slotting / Grooving

– Surface grinding